4 3 the material controller welding foreman shall monitor check his welder s portable oven quivers are plugged to power source all the time.

Welding consumable handling procedure.

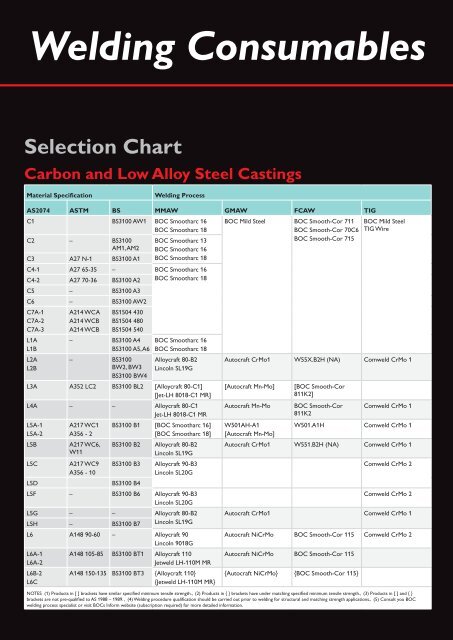

Selection of the welding consumables is the responsibility of contractor.

1 1 storage conditions.

A page 5 of.

When issuing welding consumables from storage for welding where there is a significant difference in temperature between the two areas products should be allowed to reach the ambient temperature of the welding fabrication area before the packaging is opened.

Shall conform to api standard api 650 section 2 2 shall closely match the base metal chemistry.

3 heat lot no.

Management of welding consumables 1.

Issues of consumables are to be recorded on consumable issue report.

Welding operators must keep strips as clean and protected as possible.

At the end of the day he shall gather all quivers and take to the welding material control room.

The summary below provides guidelines as to the proper storage of stick electrodes flux cored wires metal cored wires and solid wires mig wire and tig cut length.

Once removed from the original protective packaging flux cored wires should be used within 72 hours.

If relative humidity exceeds 60 cored wires should not be left unprotected for more than 24 hours.

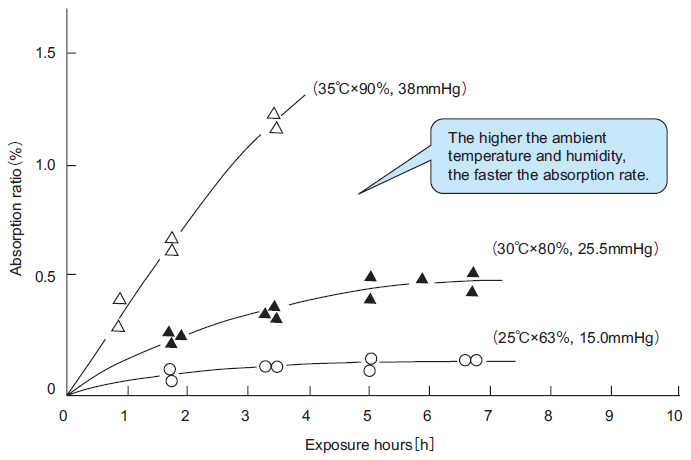

Covered electrode handling and keeping standards of electrodes sufficiently dried welding consumables do need the storage in order to prevent from re moisture absorption during taking in and out the goods by employees.

This will avoid possible contamination with condensation.

4 3 welding filler material.

Welding consumable control procedure page.

Moreover it s recommended to place the drying case maintaining 100 120 c around.

Off while welding or if there is a noticeable difference in handling or arc characteristics such as insufficient arc force.

Welding consumables handling procedure table of content 1 general 2 receiving and receiving inspection 3 welding consumables store 4 welding consumables ovens 5 disbursement of welding consumables 6 return or reassignment of unused filler material 7 optional welding consumables color coding 8 attachments.

Adequate storage handling and re conditioning of electrodes vary according to type.

And storage procedure.

1 1 0 scope this procedure describes the minimum requirements to be complied with for receipt storage issue handling and treatment of welding consumables prior to use in order to ensure acceptable weld quality during fabrication erection.

Electrodes to be re dried should be removed from the can and spread out in the oven because each electrode must reach the drying temperature.

3 of 7 rev.